KEY ELECTROCHEM LIMITED CO.

Menu

Mold cleaning process was a mandatory process for Semiconductor to clean away the epoxy deposits formed during the molding process for Integrated Circuit, Diodes, transistor etc. Cleaning method includes the Melamine Based Cleaner and Rubber Base mold cleaner. End users shall apply different combination of cleaning methology depend on cost factors, internal requirement, customers requirement as well as productivity aspect. Rubber Sheet cleaner is a fast cure material compare to Melamine base cleaner. It does not need any lead frame and preheating for performing the cleaning process. With the elimination of preheating and shorter cure time, customer can gain productivity improvement with Rubber Base Cleaner. This will also prolong the mold tool life since this rubber sheet don’t require higher pressure (clamping pressure) and unlike melamine/compression type that causing some problem such as mismatch and offset on the product specially for insert type cavity and guide pin due to excessive melamine compound inserted during mold cleaning causing cavity and guide pin to have slight movement overtime.

Specially formulated compound for the cleaning of thermosetting transfer mold. It has its excellent elastic properties which easing the removal of the compound from the mold without leaving any unwanted debris and assist in the house keeping of the molding station. Besides , it was also formulated with high flow characteristic to achieve cleaning efficiency. It emits limited odor during the cleaning process.

ADVANTAGES & BENEFITS

Specially formulated compound for wetting and conditioning of thermosetting transfer mold after mold cleaning. Elastowet has good compatibility with Rubclean. It also has excellent elastic properties to ease the removal of cured rubber after molding.It also has high flow characteristic to ensure rubber wax flow into all cavities to achieve waxing homogenous during the conditioning process.

APPLICATION PROCEDURES

Our current TOP CORE products includes:

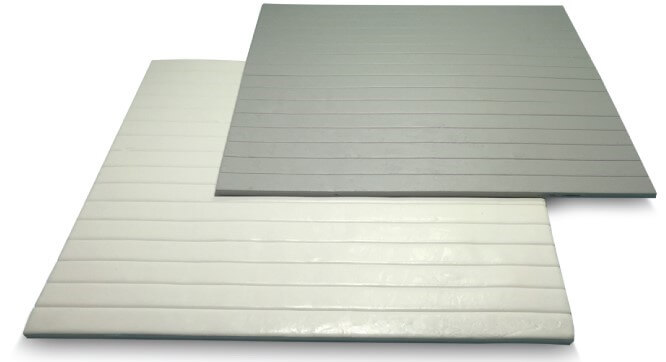

1.MOLD CLEANING RUBBER SHEET

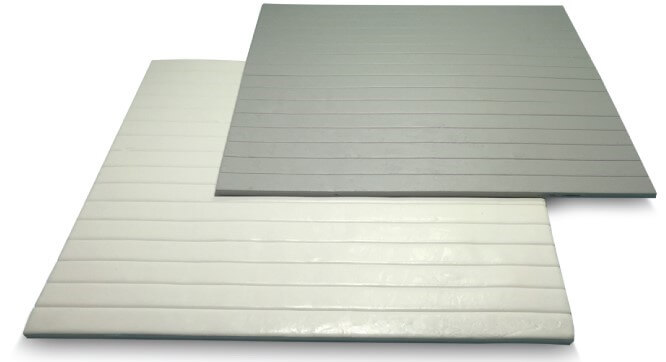

2.MOLD CONDITIONER

Our sales and technical service colleagues and our regional agent partners are highly motivated, well trained and strongly committed in providing total customer satisfaction. With the Customer-First priority, we have achieved a strong record of proven sales and services and satisfied customers stringent requirements and high expectations.

MOLD CLEANING IN SEMICONDUCTOR

Mold cleaning process was a mandatory process for Semiconductor to clean away the epoxy deposits formed during the molding process for Integrated Circuit, Diodes, transistor etc.

Cleaning method includes the Melamine Based Cleaner and Rubber Base mold cleaner.

End users shall apply different combination of cleaning methodology depend on cost factors,

internal requirement, customers requirement as well as productivity aspect.

Rubber Sheet cleaner is a fast cure material compare to Melamine base cleaner.

It does not need any lead frame and preheating for performing the cleaning process.

With the elimination of preheating and shorter cure time, customer can gain productivity improvement with Rubber Base Cleaner.

RUBBER SHEET

Specially formulated compound for the cleaning of thermosetting transfer mold. It has its excellent elastic properties which easing the removal of the compound from the mold without leaving any unwanted debris and assist in the house keeping of the molding station.

Besides , it was also formulated with high flow characteristic to achieve cleaning efficiency. It emits limited odor during the cleaning process

ADVANTAGES & BENEFITS

üAir vents, cavities and mold surfaces cleaning & conditioning in single step.

üCost saving in total cleaning materials.

üShorter cleaning time & productivity gain.

üCater for green compound requirements.

üEnvironmental friendly, using non hazardous ingredients and Halogen Free.

üNo preheat, no thawing time is needed.

üSuitable for semiconductor, optoelectronics, rubber, plastic and metal molding industries.

Specially formulated compound for wetting and conditioning of thermosetting transfer mold after mold cleaning. KWC has good compatibility with Rubclean. It also has excellent elastic properties to ease the removal of cured rubber after molding. It also has high flow characteristic to ensure rubber wax flow into all cavities to achieve waxing homogenous during the conditioning process.

APPLICATION PROCEDURES